HALO® 1.5 - a new dimension in Chromatography

Increase the performance of your UHPLC system with the new HALO® 1.5 columns.

More sensitivity

- increased signal in comparison to columns with ID 2.1 mm

- higher efficiencies in comparison to columns with ID 1.0 mm

Higher ionization efficiency

- higher intensity in MS detection due to reduced flow rate and smaller peaks

Up to 49 % reduced solvent consumption

- the smaller ID leads to lower optimal flow rates without sacrificing speed

Easy to implement microflow solution

The new 1.5 mm ID columns with 2.7 µm Fused-Core material are available for the analysis of small molecules as well as bio molecules.

More Sensitivity

Increased detector signal response from UHPLC and LCMS systems.

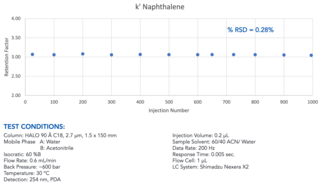

Stability

Reduced solvent consumption

How to further optimize the system

Refer to the HALO® 1.5 Brochure from page 10 for more detailed information

- The smaller the internal diameter of the column the higher the pre- and post column impact of extra column dispersion on the result.

- Therefore extra attention should be paid to connectors and capillaries. AMT recommends MarvelXACT® finger-tight fittings and capillaries to minimize band broadening.